All of us wince at the sharp sting of the syringe. While most people might get jabbed only occasionally, globally, 150-200 million people with diabetes need insulin injections twice a day. Microneedle patches can help inject insulin just below the skin surface without pricking deep like normal syringes. However, microneedles are manufactured using complex procedures like photolithography that require clean rooms, and are time consuming. This complexity limits their mass production and self-administration.

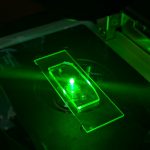

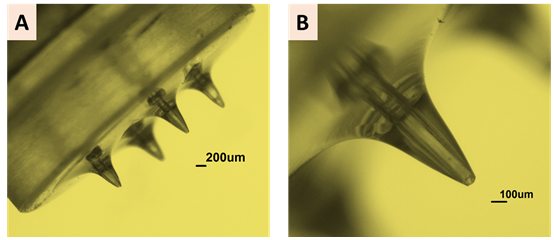

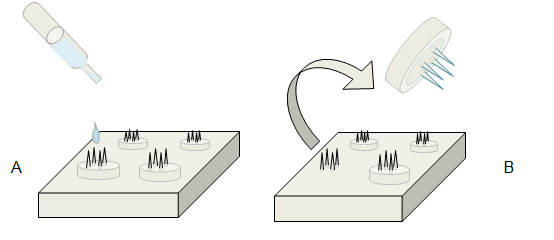

To overcome this limitation, researchers at IISc and inStem have used a novel method to produce microneedles. It involves a single-step process where the polymeric microneedle batter (a specific polymer mix) can be poured onto a platform with needle-shaped moulds which have pyramidal tips that can be adjusted to any height. As the batter (polymer mix) solidifies, a perfectly lined up array of hollow microneedles can be peeled off immediately and the setup is ready to produce the next batch right away. This kind of setup does not require an expensive clean room.

The team then tested a microneedle patch produced using this method and found that it could precisely deliver the required volume of insulin to diabetic mice in the lab. The researchers hope that this method can fasten the fabrication process of microneedles which can be used to deliver drugs as part of wearable devices.

(Image: Anu Renjith)