Sanjiv Sambandan’s research promises novel electronic devices that can bend and fold

During Sanjiv Sambandan’s undergraduate days as an electrical engineering student at IIT Kharagpur, he was introduced to the world of flexible electronics, especially the work being done at the University of Waterloo in Canada, where he would eventually pursue his PhD. His research was on flexible electronics on plastic substrates, an idea that he thought was “very cool.” Following his doctoral studies, he worked at Xerox PARC in California, where he explored a diverse range of research, paving the way for a genuinely interdisciplinary academic career.

In 2010, he decided to return to academia and applied for a faculty position at IISc. “At some point, the academic bug begins to bite,” recalls Sanjiv, who got the job and returned to his hometown, Bangalore, as an Assistant Professor in the Department of Instrumentation and Applied Physics (IAP).

Sanjiv’s IAP lab attempts to solve fundamental problems of flexible electronics and semiconductor physics. His group uses this research to build thinfilm transistor-based integrated systems. Flexible electronics does not use wafers like silicon or gallium arsenide, commonly employed in conventional electronics. Instead, the main focus here is to make thin-film transistors by depositing a layer of patterned semiconductor on flexible materials like textiles and plastics that can bend and fold. Electronic circuits printed on such flexible substrates hold enormous promise: they have the potential to enable futuristic devices with rollable displays, e-paper, smart wearable sensors and transparent Radio-frequency ID tags.

In the quest for flexible electronic systems, Sanjiv’s lab tries to take advantage of the impact of geometrical, mechanical and electrical stresses on thin film devices, a phenomenon that other engineers usually regard as a problem in flexible systems. He and his team have been exploring how this handicap can be turned into an advantage. In this process, they have invented devices and circuit techniques for flexible electronics, including the adaptive dielectric thin film transistor, corrugated thin-film transistor and self-compensating circuits.

Another aspect of Sanjiv’s lab involves interdisciplinary research that studies the behaviour of dispersions in electric fields, biodegradable electronic materials and so on. This research has led to innovations such as self-healing circuits and self- assembled sensors and actuators. Such interdisciplinary research has also led to technology translation. A shining testament to this is the lab spinoff that aims to treat wastewater.

One of Sanjiv’s students, Aswathi Nair, explored how dispersions behave in an electric field for her MTech thesis. These questions led to the genesis of Openwater.in, a startup that specialises in treating wastewater. It employs a technology that builds on electrocoagulation, a well-known technique used to treat waste suspended in water. Electrocoagulation involves changing the particle surface charge, causing the suspended particles to agglomerate, which can then be separated. Using insights from this research, Sanjiv’s lab came up with a cost-effective process of enhancing electrocoagulation, ensuring that agglomerates are formed more aggressively and at lower power.

Since 2017, Openwater.in, supported by grants from the Government of India’s Department of Biotechnology, has been able to build systems that treat up to 10,000 L of wastewater per day. The startup is currently involved in several government projects and has plans to set up several groundwater, industrial discharge and grey water treatment plants across the country, including one at Mavallipura that can generate 25,000 L of potable water per day. Although Openwater.in is working exclusively with the government, several apartment complexes have also sought the help of the startup to treat their grey water.

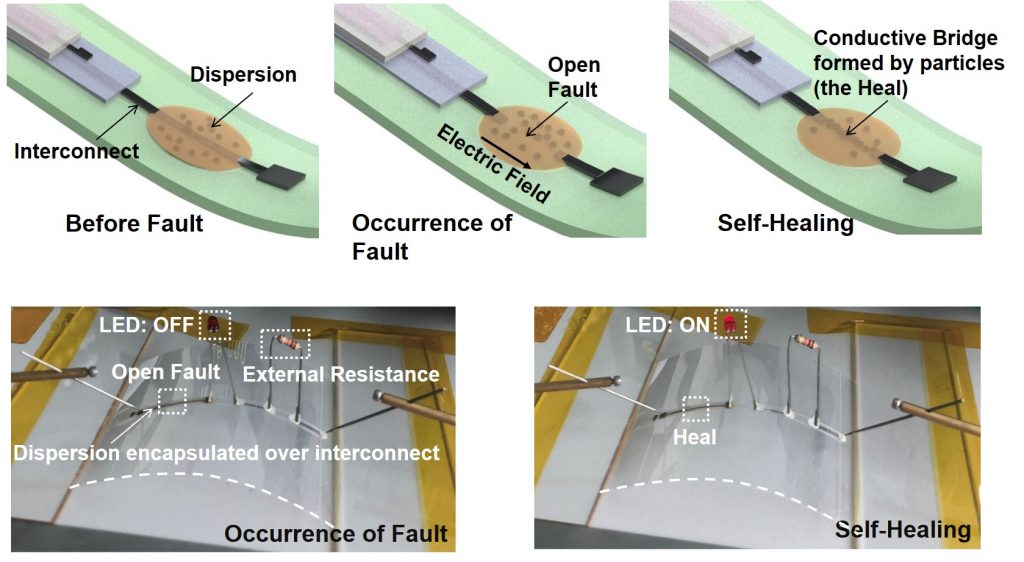

Sanjiv’s research on flexible electronics has also received widespread attention, particularly his recent work on developing “self-healing” circuits. In flexible materials, stretching causes circuits to break, thus reducing the lifespan of wearable electronics. To help address the problem, he mooted the idea of electronic circuits which repair themselves. The self-healing mechanism kicks in to repair open circuit faults by using dispersions of oil and metallic microparticles smeared over connections between various circuit elements. If a fault occurs in the connections in the circuit, the electric field polarises the metallic particles and forces them to bridge the gap. The particles are fixed in place by sintering once the flow of current is restored.

Another fascinating foray for Sanjiv’s lab has been in, believe it or not, edible electronics. Edible electronics uses benign, and often food-grade, materials like sugar, proteins and silver thin films to form circuits. His team aims to use this technology to make edible pills that can perform diagnostic tests to yield a ‘yes’ or a ‘no’ answer, without supervision from a doctor. Sanjiv believes that this will serve a niche area of diagnosis between traditional invasive tests that need a doctor’s precious time and wearable fitness gadgets that are often inaccurate in their diagnosis. However, the challenge for his lab in the coming years will be to integrate sub-systems and make these pills safe for humans to ingest.

Sanjiv, now Associate Professor, is delighted with what he has achieved as a researcher at IISc. “I have been an electrical engineer doing interdisciplinary work. All of it has been encouraged and taken positively here.” A decade-long career as a researcher at IISc has also seen Sanjiv mentor several students from all over India. Based on his experience as a mentor, he has a message for those just starting their research careers: “Explore a lot. Do not restrict yourselves. Be creative like a child.” He also urges students to go back to the basics of their subject of interest. “Focus strongly on the fundamentals.”