Rajamalli’s lab focuses on designing materials for OLED applications

LEDs or light emitting diodes have become part and parcel of our daily life, from the lights used in Diwali festivities to displays like TV and computer screens. These are minute semiconductors that convert electrical energy into light. However, LED display panels need backlighting and are not flexible. OLED (Organic LED) displays, on the other hand, are self-emissive and do not need back lighting panels, and hence they can be ultrathin and flexible. Foldable laptops and rollable TVs are therefore possible using OLED technology.

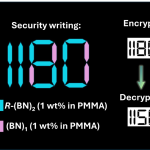

But conventional OLEDs are made of noble metal (iridium or platinum) complex-based emitters, which are expensive and not sustainable. In addition, the operational lifetime of blue iridium complex-based devices is not long. To improve this lifetime, industries use poorly performing blue emitters instead of blue noble metal complexes, which makes the devices consume more power. Therefore, either the efficiency of the OLED or its lifetime has to be compromised. Solving this issue of balancing stability with efficiency of OLEDs is what the lab of P Rajamalli at the Materials Research Centre (MRC) is focused on.

Rajamalli hails from a rural background. Even after scoring well in the 10th and 12th standards in the science stream, she was unsure of which way to go. “I liked science, but I didn’t know the direction. But [my] teachers guided me to join college,” she says. She ended up choosing chemistry as she was told that there were more job opportunities in academia and industry due to the demand for pharmaceuticals. During her MSc, she got interested in organic chemistry, while working on developing new organic compounds for her Master’s project. She joined industry for a short while after her Master’s, but held on to the hope of doing a PhD, which led her to join IIT Madras.

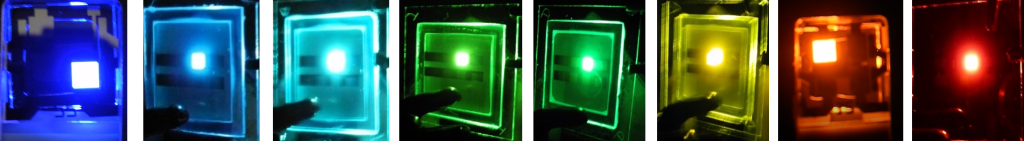

It was during her PhD that Rajamalli embarked on a journey to explore dendrimer-based luminescent molecules. The broad range of colours that could be generated when developing molecules for OLEDs captivated her. “Each of the molecules I synthesised started giving out different emissions – blue, green or red. Then, by fine-tuning the structure, I could change the colours from just the primary to whatever I liked. With blue, I could get an array of blues,” Rajamalli recollects.

By tweaking small functional groups in certain molecules, she was also able to get colours extending to the UV range. However, she was unable to properly test which molecules could be used to fabricate OLEDs, as it was not the original focus of her PhD. She would run around the physics departments at IIT Madras to enquire whether they could measure the electro-luminance of her molecules but was not very successful. However, that did not stop her. “When we don’t get something, we become more interested in doing something related to it,” she asserts.

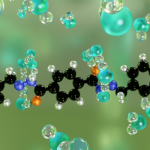

Rajamalli then decided to do her post-doctoral research at the National Tsing Hua University, Taiwan. Given a choice between organic synthesis and OLEDs, Rajamalli chose the latter. “I told them that I wanted to work on OLEDs because my dream was not fulfilled during my PhD.” And thus began her journey of designing luminescent molecules. She focused primarily on TADF (Thermally Activated Delayed Fluorescence) molecules, which have the ability to convert energy to light and enhance the performance of the device. The advantage of a TADF molecule is that it is a purely organic compound and performs just as well as a noble metal complex. Another fact which makes TADF emitters important is that there is no heavy metal in them, and the organic compounds can be obtained at a lower cost than noble metal complexes. This in turn reduces the burden on importing heavy metals. “Iridium is very rare, and the usage is also heavy. So, at some point, we may finish it all up. But we cannot shut down all the display industries, right?” Rajamalli remarks.

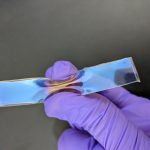

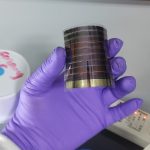

Afterwards, Rajamalli moved to the University of St Andrews in the UK for another postdoc as a Marie Curie Fellow. While she was still working on OLEDs, she switched to a new fabrication process which was different from the one she had used in her previous postdoc. “I started to focus on solution processing [basic spin-coating]. During my first postdoc, I had focused on vacuum deposition [thermal evaporation under high vacuum pressure],” recalls Rajamalli. She then joined IISc as an Assistant Professor at MRC in 2019.

Rajamalli’s research group currently focuses on synthesising blue OLEDs because there are no stable blue emitters with high performance. The lab aims to design new blue TADF materials which have both high performance and stability. Their main objective is to understand what causes the molecules to degrade under operational conditions, and how this can be mitigated. Rajamalli explains that they first try to understand which bond is fragile by observing them at a molecular level. “We will be then able to come up with new molecules which have the most stability.”

The lab is also working on devices that can generate hyper-fluorescence. “It is the fourth generation of OLEDs. TADF was the third,” elaborates Rajamalli. TADF OLEDs offer good performance but occupy too broad a spectrum. On the other hand, in conventional fluorescence OLEDs (the first generation), the spectrum is narrower, but the performance is low. Hyper-fluorescence OLEDs are a combination of both emitters. “We can improve the colour purity, performance and also lifetime,” Rajamalli explains. “We were able to achieve hyper-fluorescence in green colour OLEDs and are currently planning to achieve the same using deep blue TADF materials.” Her lab’s most recent work on green hyper-fluorescence using anthracene derivates was published in the Journal of Materials Chemistry C.

Moving forward, Rajamalli seeks to design flexible devices that have OLEDs using a flexible substrate instead of the conventional glass substrate. This will enable the device to be lightweight and to be made into any shape. This work is in collaboration with Caroline Murawski, a faculty member at KSI (Kurt-Schwabe-Institut für Mess- und Sensortechnik) Meinsberg, Germany, who works on optogenetics – using light to manipulate the activity of brain cells called neurons. “My collaborator fabricates flexible devices for controlling brain activity and their basic requirement is to have pure colour emitters,” Rajamalli explains.

Whenever Rajamalli hits a dead-end, she treats it as a challenge, she says. “I think about all the directions in which one can solve the issue,” she adds. This applies to logistical challenges too. “We do not have any local suppliers for OLED materials and instruments,” she points out. Therefore, supplies are expensive and also get delayed, which in turn slows down her research. She also has to depend on specific companies in order to obtain equipment like thermal evaporators. Importing an evaporator can cost a whooping Rs 5 crore. “It’s not just a matter of money. The servicing and maintenance will also be a problem,” Rajamalli remarks.

To solve this problem, Rajamalli designed her own evaporator which she now uses in her lab. Her group focuses on both synthesis as well as device fabrication to check the performance of designed molecules; hence it is easy for them to get quick feedback and redesign the molecules to get the desired colour and performance. “We designed it with the help of [companies] HHV and ProRes. We worked together on the design and they supplied the system.” It cost them much less, and about two years to finish setting up, she adds. Having dealt with such issues, Rajamalli hopes to use her experience to help other researchers. “[Since] high quality OLED materials are not available in India, in the future, I want to set up a company here supplying OLED materials to all.”

Rajamalli believes in maintaining a routine. She begins her day by making sure all the equipment is up and running in the lab. Apart from having weekly lab meetings, she also prioritises one-to-one discussions with her students. “I also ask the students to come up with their own ideas, because sometimes they can come up with a better idea than me,” she says.

Pursuing a career in science has been quite interesting and exciting, Rajamalli reflects. “Every day you will see a surprise. You never get bored.”