(Image courtesy: Keerthana S Kumar)

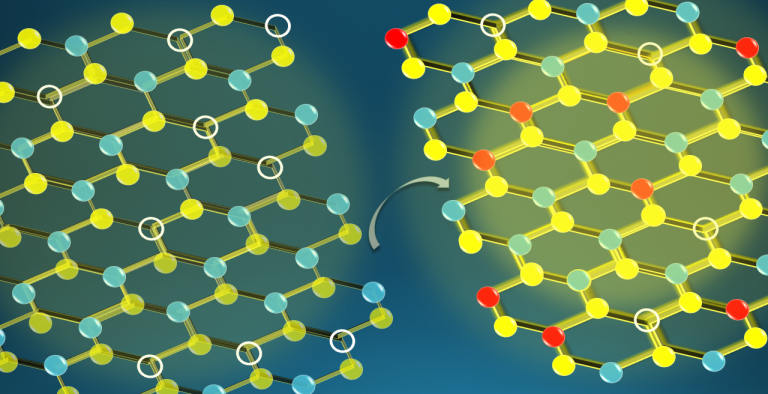

Two-dimensional (2D) transition metal dichalcogenides (TMDs) like MoS2, WS2, MoSe2 and WSe2 are promising candidates for optical, optoelectronic and energy applications. The key challenges that need to be addressed for commercialisation are scalability, repeatability and quality control. Mechanical exfoliation (ME) and chemical vapor deposition (CVD) are the two most common synthesis methods used to obtain monolayer TMDs. CVD provides repeatability and scalability but leads to high density of defects, which degrades the quality of the sample, as compared to exfoliation.

In a new study, researchers at IISc led by Akshay Singh and collaborators find that MoS2 samples created using modified (oxygen-assisted) CVD are superior in quality over regular mechanically exfoliated samples (~300% increase in room temperature photoluminescence). They differentiated the effect of defects, oxygen and strain on the optical properties of MoS2 by studying samples synthesised using different methods (ME, O-CVD) and after post-processing (hBN covering, hBN encapsulation).

The team uncovered the key effect of oxygen complexes on optical properties and showed the beneficial impact of introducing oxygen in CVD. They showed that O-CVD can be used to synthesise high-quality materials for next generation optoelectronics. By identifying the role of oxygen complexes, defects and strain, this comprehensive experimental-theoretical study has implications for applications in electronics, optoelectronics and quantum technologies.