Susmita Dash’s lab studies the science of surfaces, fluids and heat to find solutions to problems in energy, environment, and health

Growing up, Susmita Dash never thought that she would become a scientist. But that changed when she landed an internship at the Indian Institute of Technology, Kanpur, while pursuing her bachelor’s degree. It was here that she was exposed to the world of experimentation. During the internship, she studied how ink flow patterns form when an oscillating circular cylinder is suspended in a liquid stream. This experience kindled a fascination in her for research. “I loved seeing what I saw … research looked fun,” she says.

After her bachelor’s degree, Susmita took a short diversion from academia to industry and joined Schlumberger, an oil and gas company, as a mechanical engineer. But she couldn’t resist the lure of academia. “I liked research, I wanted to be a researcher,” she says. She took up a PhD programme at Purdue University, USA. After graduating from Purdue, Susmita pursued her post-doctoral research at the Massachusetts Institute of Technology for two and half years. She then joined IISc as an Assistant Professor in the Department of Mechanical Engineering in January 2018.

Susmita’s lab focuses on understanding how heat, fluids and material surfaces interact with one another at various scales, from the micro to the macro. They seek to develop solutions for global-scale challenges related to energy and transport.

One area of interest is thermal management – the control and regulation of heat in a system or device. This is crucial in many areas such as electronics and automotive engineering, where excessive heat can cause damage to or reduce the efficiency of a system. “There is an ever-increasing demand for power, which creates a need for efficient thermal management techniques … often electronic devices are limited by their ability to dissipate heat, or how fast they can be cooled,” Susmita says. Her team works on ways to maximise heat transport and increase device productivity.

Along the same lines, her team is working towards designing and developing, and thrust characterisation of micro-thrusters that rely on localised evaporation of the propellant for propulsion of nanosatellites. Such nanosatellites, which are helpful for low-cost communication and surveillance, require compact and lightweight propulsion systems. The microthruster utilises a green propellant – water – as the working fluid. There are, however, several challenges in this area, which her group is currently working on. “The device needs to adapt to vacuum conditions and low temperatures,” says Susmita.

Another challenge that the lab attempts to address is fouling – the build-up of undesirable particles on a surface. This can happen in a variety of situations, such as when salt accumulates and clogs pipes and heat exchangers. Fouling can have negative effects on the performance and efficiency of a system, and so it is important to understand and prevent it.

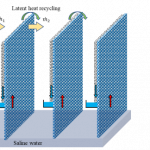

The lab also conducts research on desalination – the process of removing salts, minerals, and other contaminants from water, to make it fit for human consumption or irrigation – using solar energy, which is a low-cost, sustainable alternative compared to fossil fuels. Traditional desalination units convert saline water to vapour using the rays of sunlight. This vapour then cools down and gets collected as distilled water. But existing desalination systems are not very efficient at recovering large volumes of fresh water and also consume a lot of power. To overcome this problem, Susmita and her team are working on developing an efficient solar thermal desalination system by primarily focusing on improving the efficiency of the condenser. For this, they employ the concept of surface wettability – the tendency of a liquid or a gas to spread and interact with other liquids and solids surfaces – and wicking. “Think of it like a sponge. When placed over water, the water gets absorbed (wicked) because of the sponge’s tiny capillaries, which help collect the liquid,” Susmita explains. The team uses the same strategy: a conducting substrate dipped in liquid on one side and exposed to sunlight on the other.

Food safety is yet another area that the lab works on. A recent study from the lab made headlines for offering a low-cost approach to detect adulterants in milk. In the study, Susmita and her team showed that evaporative deposition can help detect the presence of common adulterants in milk, such as water and urea, by observing changes in the patterns generated by non-volatile milk solids and the crystallisation of urea.

Like other young researchers, Susmita also found the early days of being a faculty member challenging: setting up an experimental lab, and teaching courses. The second part was particularly intimidating for her in the beginning. “When you are a new faculty member and are teaching the course for the first time, you are as nervous as the students … how to plan the course materials and how to put across the concepts so that the class understands … but when you want to learn something properly, the best way is to teach,” Susmita explains.

In research, one has to “grease their own gears,” she says, explaining that students have to constantly keep thinking of new approaches to their research problems, and think and plan their work independently.

Although mechanical engineering has historically been a male-dominated field, Susmita believes that the gender gap can be reduced by increasing awareness among school students about the exciting possibilities the field has to offer. Mechanical engineering is becoming more and more interdisciplinary, offering people from diverse backgrounds opportunities to pursue cutting-edge research. “People think that if you are a mechanical engineer, you have to hold a spanner, tighten a screw, or fix a machine, but that is not the real picture,” she says.