Scientists at the Materials Research Centre (MRC) have developed a new type of enzyme mimetic that can degrade toxic chemicals in industrial wastewater effectively in the presence of sunlight.

Enzymes are proteins that catalyse a majority of biological reactions in living systems. However, the practical use of natural enzymes is greatly hindered by certain inherent limitations. These limitations include sensitivity to denaturation (breakdown/damage), complex production procedures, high costs, and difficulties in recycling, says Subinoy Rana, Assistant Professor at MRC and corresponding author of the paper published in Nanoscale.

Mass producing these enzymes is an expensive and time-consuming process. For example, laccase, a natural enzyme used for degrading phenols in industries, is extracted from a fungus called white rot, but the amount of enzyme produced depends on how much of the fungus is available at a given time. “It’s a long process and it’s difficult to make them in more than milligram amounts,” says Rana. Another problem is storage – most of the natural enzymes are temperature-sensitive and require storage at cooler temperatures, often as low as -20°C.

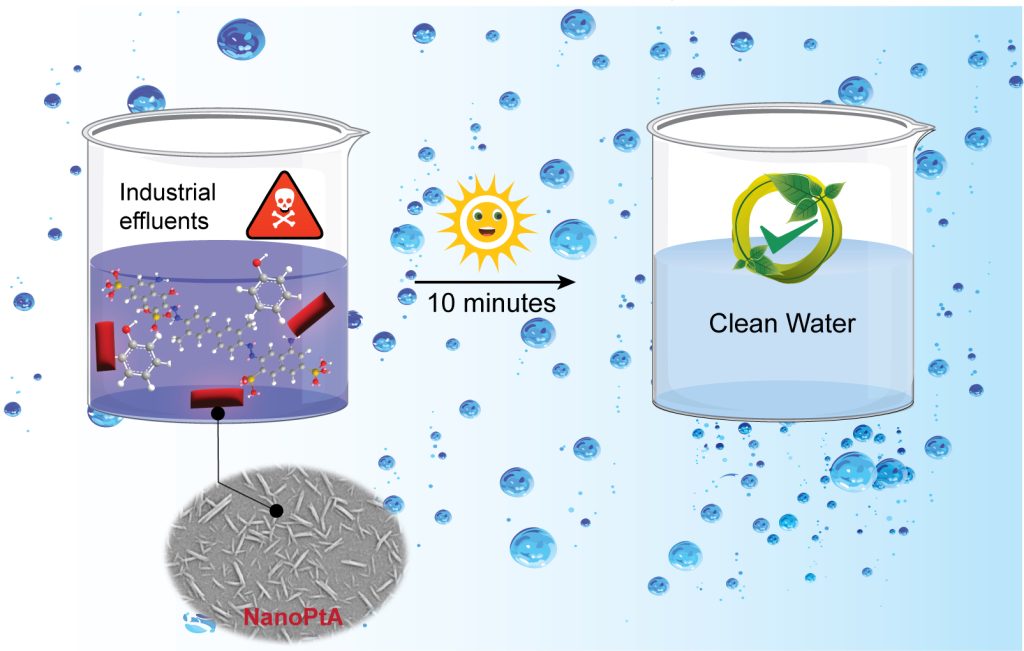

Nano-sized enzyme mimetics or “nanozymes” manufactured in the lab can mimic such natural enzymes and overcome these practical challenges. In the current study, the IISc team synthesised a platinum-containing nanozyme called NanoPtA, which can be converted into powder form for industrial use. It mimics the function of oxidases – natural enzymes that remove hydrogen from substrates in the presence of oxygen to give water. This nanozyme is not only highly specific in breaking down certain substrates but is also robust because it can withstand a range of pH and temperature changes.

When the NanoPtA comes in contact with wastewater, the benzene rings and long alkyl chains present in the molecule form multiple non-covalent interactions. Individual NanoPtA molecules connect together to form tape-like structures that start emitting light, which is the origin of its oxidising capacity. The nanozyme can then degrade pollutants present in wastewater by oxidising them in the presence of sunlight, thereby reducing the toxicity of wastewater.

The team tested the nanozyme’s effect on common effluents that pollute water, like phenols and dyes. They found that it could degrade even small (micromolar) quantities of phenols and dyes within ten minutes when placed under sunlight. The researchers also found that the NanoPtA complex was quite stable, lasting for up to 75 days at room temperature. “Proteins are generally stored at -20°C or 4°C, but in this case, it can be stored at room temperature,” says Rana. In fact, the NanoPtA was stable for more than six months at room temperature, the researchers found.

The team believes that the nanozyme is not only useful for breaking down toxic pollutants but can also have applications in healthcare. They tested its ability to oxidise neurotransmitters like dopamine and adrenaline – when oxidised, these molecules show a change in colour in solution, which can then be used to measure their concentration. “This is important because these neurotransmitters are associated with Parkinson’s, Alzheimer’s disease, and cardiac arrest,” says Rohit Kapila, first author and PhD student at MRC, IISc. Measuring these neurotransmitters using such nanozymes can potentially be a useful diagnostic tool for neurological and neurodegenerative diseases, he adds.

Moving forward, the researchers plan to patent the nanozyme, as they believe it can be readily manufactured in large quantities on an industrial scale. Rana’s group is also looking at less expensive metal alternatives to platinum in the nanozyme complex.