How research labs at IISc are trying to follow sustainable practices

In 2015, three researchers from the University of Exeter, UK, called for action against the large amount of plastic waste generated in research labs. They estimated that around 5.5 million tonnes of plastic waste are generated in one year by scientists, who account for 0.1% of the total population.

When Shovamayee Maharana came across this statistic, she was determined to reduce the carbon footprint of her research. An assistant professor in the Department of Microbiology and Cell Biology (MCB), IISc, Shovamayee’s work mainly involves culturing cells and studying the formation of protein and RNA assemblies in live cells. This usually requires Petri dishes, which are made from plastic. “Thirty years ago, if you came to the same [cell culture] lab, people were growing cells in glass. But now, if you go to any research lab, anywhere in the world … everybody grows them in plastic,” she says, remembering that she had just become so accustomed to using plastic during her post-doc years.

When Shovamayee came to IISc, a former faculty member in MCB, S Vijaya, who headed the same cell culture lab, had left behind her glass flasks. Shovamayee asked Shobha Elangovan, one of the researchers in the lab: “Can you grow cells in this?” The latter, a former student of Vijaya currently pursuing her post-doc in Shovamayee’s lab, replied that everyone in the lab grew all important cell lines in glass flasks.

Now, Shovamayee’s lab tries to use glass as much as possible – for measuring solutions, and for growing and observing cells. Substituting glass in place of plastic is more of a “biology problem” according to Shovamayee because chemistry labs, for example, already use glass flasks to store solvents – glass is inert and doesn’t react with the contents inside.

Shovamayee also encourages her students to put together culture media (a nutrient-rich liquid in which the cells grow) from a premix powder, instead of buying ready-made media in plastic bottles. “Not only does it make you judicious about using media it also generates about 20 times less plastic,” she says.

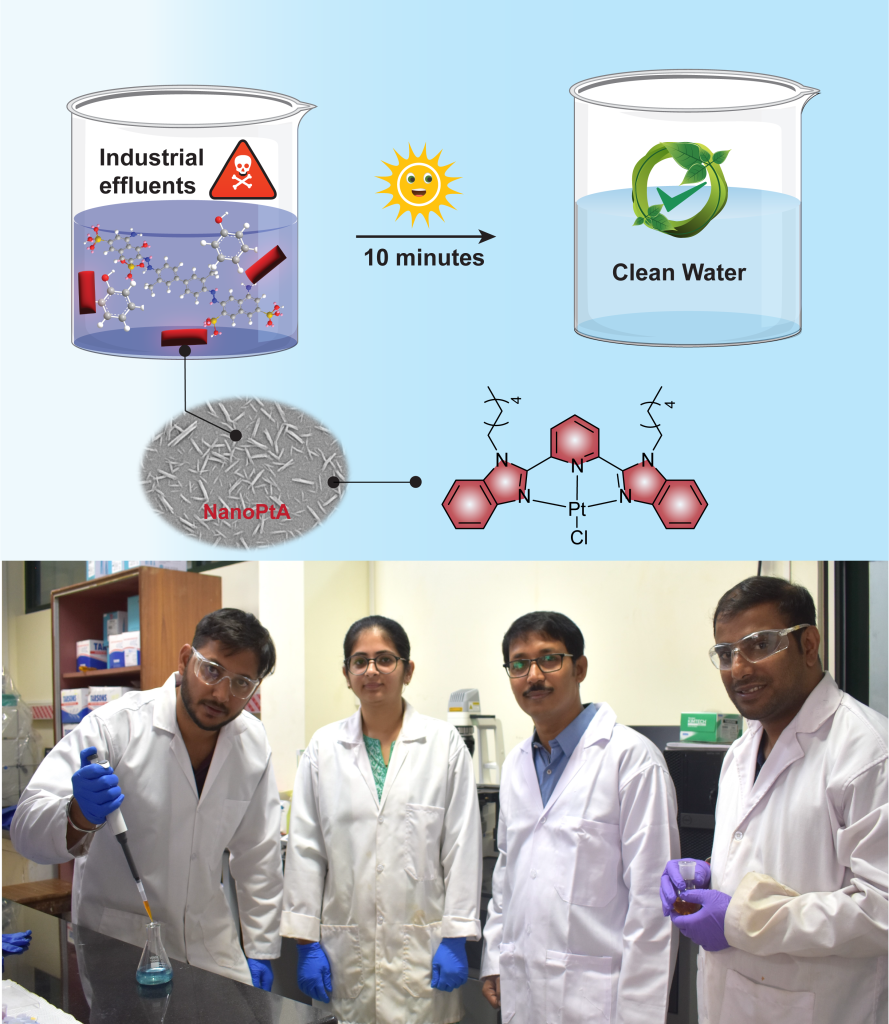

Sustainability is something that Subinoy Rana’s group – FunBioMats at the Materials Research Centre (MRC) – also strives to achieve. “Ours is an interdisciplinary group where we use chemistry for biological and environmental applications,” says Subinoy, an assistant professor at MRC. His lab recently developed an enzyme mimetic that breaks down toxic effluents in industrial wastewater in the presence of sunlight.

One of the ways Subinoy tries to implement sustainable practices is to reuse organic solvents like dichloromethane, ethyl acetate, toluene, ether and others. “We regularly use a purification step using something called column chromatography, which actually requires a lot of organic solvents … [but] you can reuse that solvent,” he says. However, this type of recycling has to be done carefully because when working on a reaction that involves a reused solvent, you have to be extra careful about contaminants.

Subinoy’s lab also ensures sustainability by not only minimising the use of plastic wherever possible but also by segregating plastic waste. He asks students to separate plastic from general waste and nitrile gloves (made up of a different type of plastic) that are used for safety.

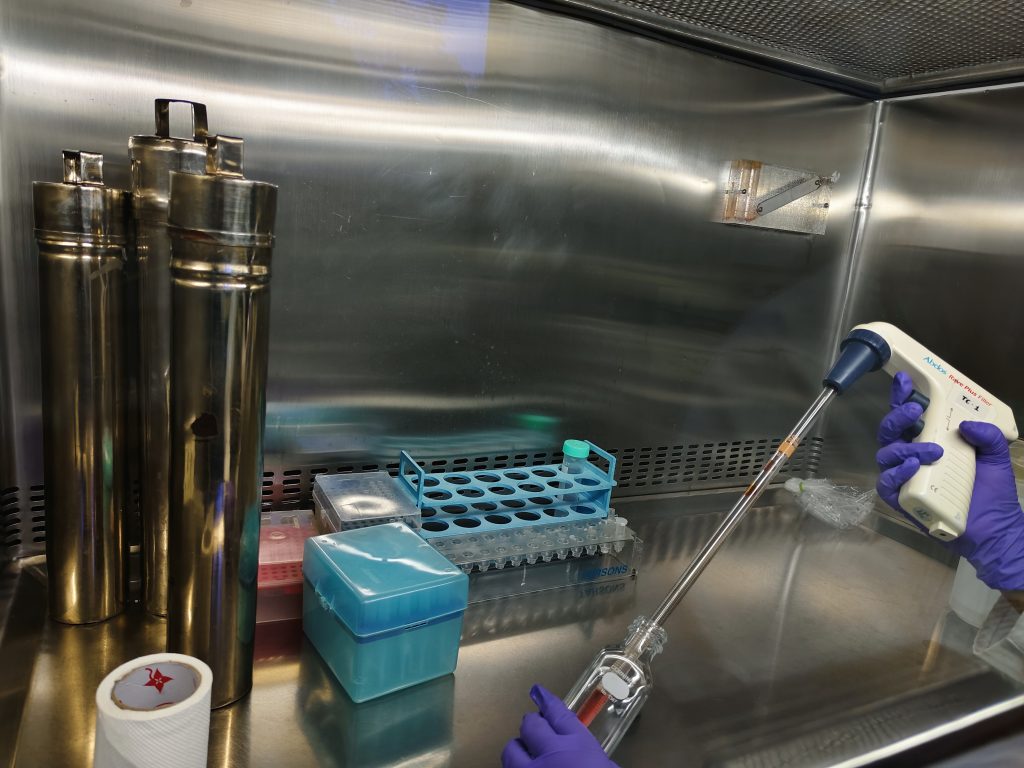

(Photo courtesy: Subinoy Rana)

Both Subinoy and Shovamayee say that their students first resisted the sustainable solutions they wanted to use in their labs – because it takes effort to purify an organic solvent or prepare media from powder. One student even asked Shovamayee why, being in a world-class institute like IISc, they should bother with making their own media. Other students were worried about how sterility can be ensured if chemicals or materials are reused. Over time, however, the faculty members managed to convince their students to follow these practices.

Here’s an example: A common instrument in both labs is the micropipette used for measuring small amounts of solvents. These pipettes come with a plastic tip, packed in a plastic cover, which is used just once. This means that every time 5 ml of solvent is measured in a micropipette, one plastic tip and one plastic cover gets thrown down the bin.

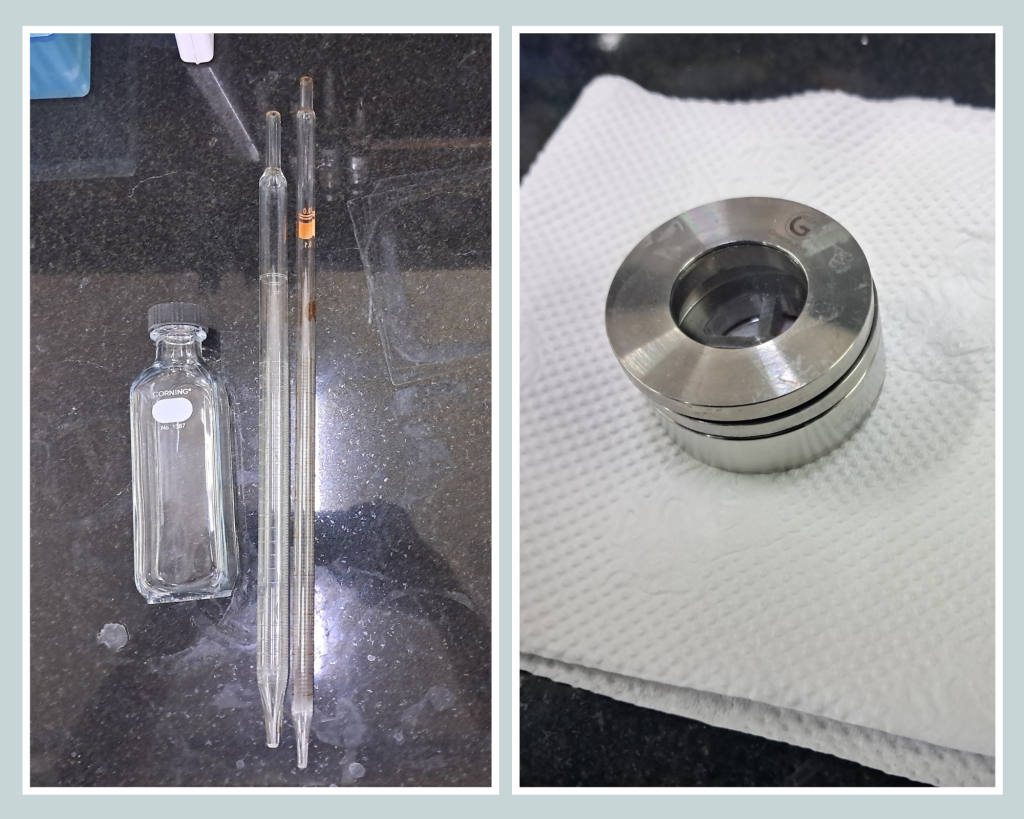

To overcome this problem, Shovamayee’s lab uses glass pipettes instead of disposable plastic ones, explains Prarthana Dastidar, a PhD student in the lab. Once a solvent is measured using these pipettes, they are placed in a sterilising solution, taken out and placed in metal canisters, then autoclaved, packed with sterile cotton on top, and only opened again inside the laminar flow hoods. Prarthana adds, “We use glass flasks that can be baked to very high temperatures – around 200 °C – to kill everything in them … [then they] become reusable for much longer.”

Sorting waste

On a cool winter morning, Masoodur Rahman sits in his office desk chair, explaining the various responsibilities of the Office of Laboratory Safety and Environmental Health (OLSEH) at IISc, where he works as a biosafety officer since 2020. The Office follows the waste management rules set by the Central Pollution Control Board and the Karnataka State Pollution Control Board. According to these rules, OLSEH partners with certified agencies to dispose of biological or animal waste, chemical and radiological waste. For the latter, the office follows the Atomic Energy Regulatory Board (AERB) guidelines.

In one year, nearly 70,000 kg of biowaste and 40,000 kg of chemical waste is disposed of by OLSEH. Earlier, this waste was not segregated before OLSEH came into action. Since then, the office has guided all 1,077 labs inside the Institute on proper waste segregation and disposal. Waste sheds are also set up in designated spots across the campus, in case there are delays in collecting waste from labs.

Rahman says that students are asked to pour certain liquid waste – like those that remain after autoclaving – down the sink. These sinks from all labs are connected to one of two in-house Effluent Treatment Plant (ETP) plants on campus. “That waste will not disturb the environment because it is directly treated in an ETP, and that water will be used in gardens and other areas,” Rahman says.

Rahman adds that it took nearly one and a half years to enforce these practices across all labs in the Institute. OLSEH thoroughly inspects all labs twice a year, but also visits them once every four months to check if waste is being segregated properly. “Every department has one safety champion … they are always in contact [with us].” Moving forward, he says that they have applied for licenses to check the quality of air in chimneys and fume hoods. OLSEH also plans to implement new software to collect more data and understand the exact status of waste generation and segregation in labs.

Challenges of green research

While switching off lights and judiciously using resources may sound easier to follow, other efforts like reducing plastic are much harder.

“One reason why people don’t use sustainability is the fear of losing time,” says Shovamayee. She suggests that investing time initially – at the time of setting up the lab – to train your students, teach people who clean the labs and finding manufacturers with the right equipment can help. But the challenge with that, she adds, is that sustainable products and equipment are more expensive, so the initial investment is usually higher. “For example, if I want to buy a reusable dish, it is going to be Rs 7,000 as opposed to Rs 500. But that Rs 500 equipment, I’ll use it just once, whereas the Rs 7,000 equipment I will probably use it 30 times more.” In the long run, this can help researchers save money as they don’t have to repeatedly order new equipment or waste time waiting for it to arrive.

Finding the right manufacturers is another challenge. Companies that manufacture glass and stainless steel pipette caps are far and few in number, as the market is shrinking, Shovamayee says. “We need more such companies and services that think of sustainability.” For instance, she asks, why not design a specific dishwasher for labs that can help clean all equipment? “It would be great if there is a chemistry guy who thinks about recycling gloves … and a company which collects all gloves and makes it again from the same materials.” Currently, she has partnered with a company called GreenFocus Research Technologies to create a reusable stainless-steel dish that can be used for live-cell imaging.

Both Subinoy and Shovamayee agree that it is hard to minimise plastic use all at once. The overuse of plastic is not just a problem in research labs, but also across the medical field, the latter points out, giving the example of how a lot of plastic accumulated from diagnostic kits and protective measures developed during COVID-19. She adds that researchers need to be flexible and open to going back to plastic in case things don’t work out.

“Getting rid of these non-green ways completely is next to impossible and may require a long time before it can be realised,” says Subinoy. However, he strongly feels that sustainability should be part of larger conversations on a research campus like IISc. “If we write a paper with a long introduction on the importance of sustainability, but don’t practice it, that is hypocrisy.”