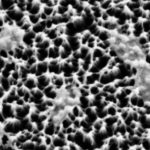

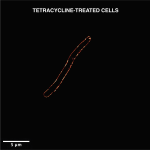

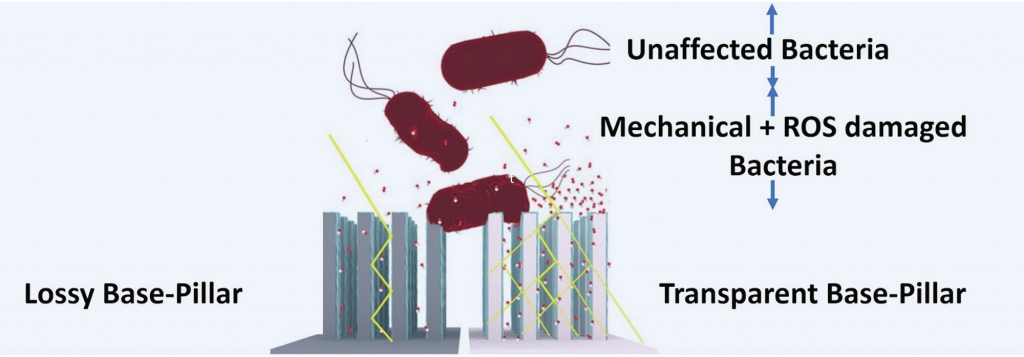

Drug-resistant bacteria often spread through surfaces such as doorknobs, public seats and medical equipment like stethoscopes. Previous attempts to develop antibacterial surfaces, by coating them with chemicals, have led to bacteria becoming drug-resistant. Another approach involves surfaces using photocatalysts such as titanium dioxide (TiO2) which on exposure to UV light generate chemically reactive molecules called Reactive Oxygen Species (ROS) that kill bacteria by disrupting their membranes. But these surfaces typically absorb light poorly and produce few ROS.

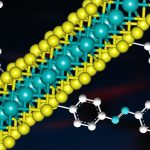

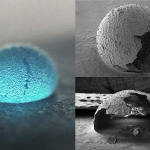

To counter this, researchers at the Centre for Nano Science and Engineering have devised a comprehensive design principle for such surfaces. Through simulations and experiments, they maximised ROS production using TiO2-coated, non-absorbing nanostructures of a particular height, and found that the best underlying material for these nanostructures is a transparent non-photoreactive material such as Black Silica. These design rules can be used to build highly efficient antibacterial surfaces in hospitals, airports, public transport, and other areas.