As the country faces a looming shortage of ventilators fueled by the COVID-19 crisis, IISc researchers have been racing against time to build home-grown solutions

A ventilator can be a life-saver for patients whose lungs are damaged by COVID-19 infection. But India, like all countries grappling with this pandemic, is likely to face a large shortage of ventilators. Manufacturers are unable to procure key components such as sensors and flow controllers from abroad due to the current disruptions in global supply chains.

To address this deficit, two research teams at IISc have been racing against time to build ventilators using locally-available parts. One of them, called Project PRAANA, successfully completed the prototype of a full-fledged ICU-grade ventilator on 29 May 2020. It took the team just 35 days to go from the drawing board to a proof-of-concept system, and then a working prototype in another two weeks.

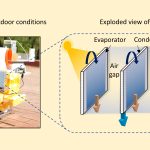

Built using a custom-designed pneumatic system controlled by a microprocessor, the ventilator uses specialised algorithms and techniques to blend air and oxygen in the desired ratio. It also has fine-grained control of patient-side respiratory parameters, and supports both invasive and non-invasive ventilation.

Patients with severe COVID-19 infection have inflamed or damaged lungs that struggle to receive sufficient oxygen. When doctors put them on a ventilator, the machine critically assists lung function, feeding the patients a controlled mixture of air and oxygen and buying their body time to fight the infection.

To build their ventilator, the PRAANA team used only components made in India or easily available in the domestic supply chains. Some parts, such as a flow rate sensor that shows how much air is flowing into the patient’s lungs, had to be developed from scratch. The team also received inputs from doctors to make the ventilator dashboard user-friendly with preloaded settings, which would make it easy for untrained nurses and technicians to operate it quickly in an emergency. It is expected to be priced in the range of Rs. 1 to 1.5 lakh per unit, which is substantially lower than currently-priced models in the Indian market.

The project was started by faculty members Gaurab Banerjee, Duvvuri Subrahmanyam, TV Prabhakar and Pratikash Panda, Bangalore-based engineer Manas Pradhan, and retired IISc professor HS Jamadagni. Many volunteers and research staff members at IISc also contributed to this initiative. The project received funding from IISc, the office of the Principal Scientific Adviser to the Government of India, Infineon Technologies and SBI Foundation. Narayana Health, Bengaluru, provided medical testing equipment.

“We are now actively exploring options to collaborate with an industry partner to further co-develop the prototype into a field-ready product,” says Subrahmanyam.

When full-fledged ventilators are scarce, in an emergency, even low-cost ventilator systems can prove critical. One such solution is being developed by another IISc team with more than 30 members, coordinated by faculty member Srinivasan Raghavan at the Centre for Nano Science and Engineering. They are adapting techniques used regularly in nanotechnology equipment such as Chemical Vapour Deposition and proportional–integral–derivative (PID) controls.

A full-fledged ventilator has sophisticated features to adjust air pressure and volume based on the needs of a patient’s respiratory system. It may cost upwards of Rs. 10 lakh and depending on the control it offers, go up to Rs 25 lakh. As an alternative, this team decided to develop a ventilator or a ventilation mechanism that would use the bare minimum of electronics, and easily interface with existing hospital infrastructure, at a cost of Rs 50,000 – Rs 1,00,000.

“After speaking to Dr. Justin Gopaldas, who works in Manipal North Hospital, we realised that while a ventilator is a sophisticated device not to be taken lightly, some patients may not need a full-fledged ventilator,” says Raghavan. “One could have cheaper solutions to cater to a large number of people needing some form of forced air or forced breathing.”

The team developed four versions, each one more complex than the previous. The basic version was a pneumatics-only variety, while the advanced version with more than 20 alarms offers mandatory and intermittent pressure, volume and pressure-regulated volume control. One of the advanced versions is currently undergoing five-day reliability trials in the lab. The team collaborated with industry partners KAS Technologies for production and Vasmed Health Sciences for biomedical expertise.